Screw Barrel Element for Masterbatch

ITEM DESCRIPTION

Screw Barrel Element for Masterbatch

Segment Screw Barrel Unit is the major plasticizing part for parallel plastic extruder machines, which normally consist of parallel segment twin screw assembles and segment barrel assembles. With decades of experience, we have massive supply for machine manufacturers and end user customers, and for machines like TOSHIBA, JSW, KraussMaffei, Berstorff, Coperion, Leistritz, Theysohn etc., we can supply screw barrels with screw diameter vary from 40~140mm, and our main focus is on PVC, PE, PET, ABS, PC conventional compounding, like fillers, masterbatch compounding, Glass fibre polymers compounding and sheet extrusions. Not only we have expertized engineer can tailor to your application and optimize your production, but also we have most advanced equipment to guarantee perfect compliant with machining requirement.

PARAMETERS:

Processing Application: Masterbatch, Pelletizing, Profile, Micro-foaming Product

Applicable Plastics: PE, PET, ABS, PC..

Screw Type: Twin Screws

Straightness:0.022 mm/m

Roughness:Ra 0.4

Processing Temperature:<400°

Material Grade:Nitrided / 6542 / Ni-based alloy / PM steel

Warranty Period:1 Year

Diameter Range: Φ34 – 120 mm

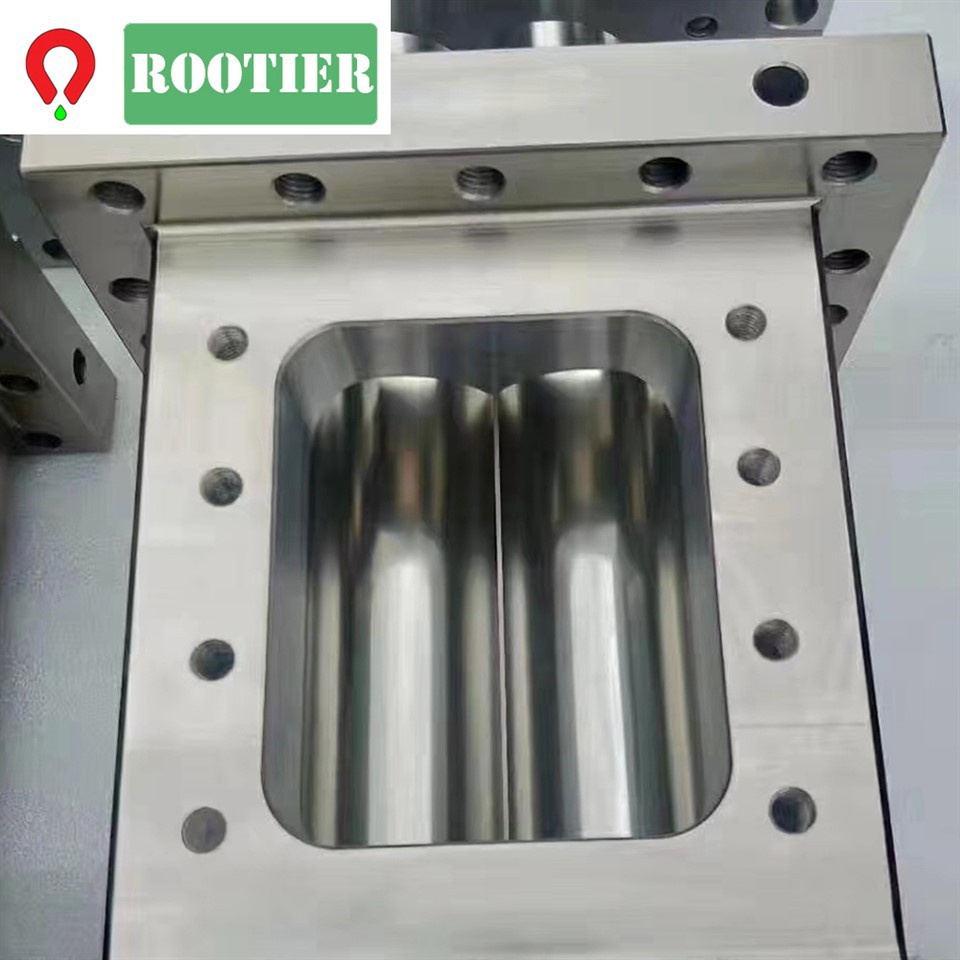

PARTS DEMONSTRATION:

APPLICATION FIELD

Why choose us?

- Our team is passionate about helping customers find the best Twin Screw Barrel solution for their needs.

- Under the leadership of the company's founder, we have gradually established comparative advantages in 'independent research and development, lean manufacturing and honest management', and formed our own core competitiveness.

- Our competitive pricing and exceptional quality make us the best choice for customers seeking twin screw barrel products.

- We achieve the goal of low cost, high efficiency, energy saving and environmental protection, and form the core competitiveness.

- Our knowledgeable staff is happy to answer any questions or concerns our customers may have about our products.

- We continue to challenge our own innovation ability, sincerely serving customers well.

- We listen to our customers' needs and strive to develop innovative Twin Screw Barrel solutions that meet their specific requirements.

- We have been working hard for enterprises to meet customers' needs and the highest level of customer service to the maximum extent and most efficiently.

- Our team of experts is committed to providing personalized service to help customers choose the right Twin Screw Barrel product for their needs.

- Our Screw Barrel Element For Masterbatch are of excellent quality, and have a leading position in technology and a high market share in the industry.

Screw Barrel Element for Masterbatch: Your Solution for High-Quality Extrusion

If you are in the plastic extrusion industry, then you know how important the screw barrel element is to your process. This is where the melting, mixing, and dispersion of masterbatch components take place. That is why you need a high-quality screw barrel element that can handle the demands of your production line.

Introducing our Screw Barrel Element for Masterbatch. Our product is designed to meet the needs of our customers who demand high-quality and reliable performance in their extrusion process. Here are some of the key features of our product:

1. High-Quality Materials

Our screw barrel element is made of high-quality materials that enhance its durability, thermal stability, and wear resistance. The materials we use are carefully selected to ensure that our product can withstand the harsh conditions of the extrusion process while maintaining its structural integrity.

2. Advanced Technology

Our screw barrel element employs advanced technology that gives it a superior mixing capability. The mixing section of our product is designed to ensure that the masterbatch components are thoroughly and uniformly mixed before being extruded. This not only improves the quality of the final product but also reduces the need for downstream processing.

3. Customizable Design

We understand that different customers have different needs. That is why we offer a customizable design that allows our customers to tailor our product to their specific requirements. Whether you need a different length, diameter, or mixing section, we can customize our screw barrel element to meet your needs.

4. Competitive Pricing

At our company, we strive to provide our customers with the best possible value for their money. That is why we offer our Screw Barrel Element for Masterbatch at a competitive price point. You can be confident that you are getting a high-quality product at a fair price when you choose our product.

5. Reliable Performance

Our Screw Barrel Element for Masterbatch is designed to deliver reliable performance, day in and day out. We understand that downtime in your production line can be costly, which is why we have designed our product to minimize the risk of failures or breakdowns. With our product, you can be confident that your extrusion process will run smoothly and efficiently.

Conclusion

In summary, our Screw Barrel Element for Masterbatch is a product that stands out in the market for its high-quality materials, advanced technology, customizable design, competitive pricing, and reliable performance. By choosing our product, you can improve the quality of your final product, reduce downstream processing, and increase the efficiency of your production line. So why wait? Contact us today to learn more about our product and how we can help your business succeed.

Hot Tags: screw barrel element for masterbatch, China screw barrel element for masterbatch manufacturers, suppliers, Weber D45 Parallel Screw Barrel, LIANSU Pipe Conical Screw Barrel, Screw elements with Barrel, Battenfeld Parallel Screw Barrel, 35 75 JWELL Conical Screw Barrel for PVC, 45 90 JINHU Twin Conical Screw Barrel

You Might Also Like

Send Inquiry