As a seasoned supplier of Twin Screw Barrels, I understand the critical role these components play in various industrial processes, especially in extrusion operations. Selecting the right twin screw barrel is not a decision to be taken lightly, as it can significantly impact the efficiency, quality, and profitability of your production. In this blog, I'll share some key factors to consider when choosing the perfect twin screw barrel for your specific needs.

1. Material Compatibility

The first and foremost factor to consider is the compatibility of the twin screw barrel material with the materials you'll be processing. Different polymers, plastics, and other materials have unique chemical and physical properties that can interact with the barrel material in various ways. For example, some materials may be highly abrasive, requiring a barrel made from a wear-resistant material such as tungsten carbide or high-chromium alloy. On the other hand, materials that are chemically reactive may need a barrel with a corrosion-resistant lining, like stainless steel or nickel-based alloys.

When evaluating material compatibility, it's essential to understand the specific requirements of your production process. Consider factors such as the melting point, viscosity, and chemical composition of the materials you'll be extruding. If you're unsure about the best material for your application, consult with a material expert or the manufacturer of the twin screw barrel. They can provide valuable insights and recommendations based on their experience and knowledge.

2. Screw Configuration

The screw configuration of the twin screw barrel is another crucial factor that affects its performance. The screw design determines how the material is conveyed, mixed, and melted within the barrel. There are several types of screw configurations available, each with its own advantages and disadvantages.

- Co-rotating Screws: Co-rotating twin screw barrels are the most commonly used type in extrusion applications. They offer excellent mixing and conveying capabilities, making them suitable for a wide range of materials and processes. The co-rotating screws rotate in the same direction, creating a positive displacement effect that helps to transport the material through the barrel.

- Counter-rotating Screws: Counter-rotating twin screw barrels are less common but offer some unique advantages. They provide a high degree of shear and mixing, making them ideal for applications that require intensive compounding or dispersing of additives. The counter-rotating screws rotate in opposite directions, creating a complex flow pattern that enhances the mixing efficiency.

- Single-flighted and Multi-flighted Screws: Screws can also be classified based on the number of flights they have. Single-flighted screws have a single helix, while multi-flighted screws have multiple helices. Multi-flighted screws offer higher conveying capacity and better mixing performance compared to single-flighted screws. However, they also require more power to operate.

When choosing a screw configuration, consider the specific requirements of your production process, such as the type of material, the desired output rate, and the level of mixing required. You may also need to consider the compatibility of the screw configuration with the rest of your extrusion equipment.

3. Barrel Design

The design of the twin screw barrel also plays a significant role in its performance. The barrel design affects factors such as the material flow, heat transfer, and pressure distribution within the barrel. There are several types of barrel designs available, each with its own unique features and benefits.

- Single-barrel and Multi-barrel Designs: Single-barrel twin screw extruders have a single barrel that houses both screws. They are relatively simple and cost-effective, making them suitable for small-scale production or applications with low output requirements. Multi-barrel twin screw extruders, on the other hand, have multiple barrels that are connected in series or parallel. They offer higher output rates and better control over the extrusion process, but they are also more complex and expensive.

- Jacketed and Non-jacketed Barrels: Jacketed barrels have a hollow outer layer that can be filled with a heating or cooling medium, such as water or oil. This allows for precise control of the barrel temperature, which is essential for maintaining the quality and consistency of the extruded product. Non-jacketed barrels, on the other hand, rely on external heating or cooling sources to control the temperature. They are simpler and less expensive than jacketed barrels, but they offer less precise temperature control.

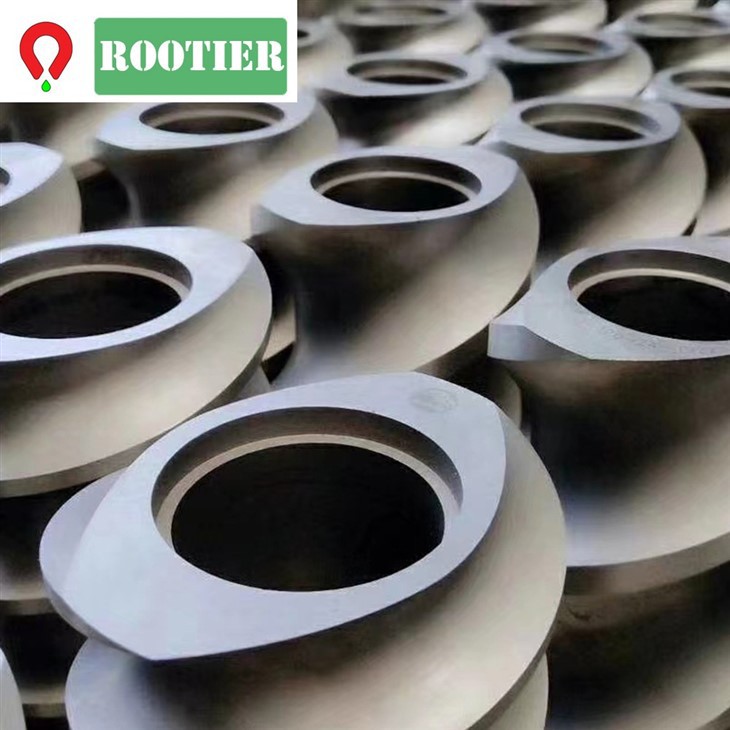

- Lined and Non-lined Barrels: Lined barrels have a thin layer of a different material, such as tungsten carbide or ceramic, applied to the inner surface of the barrel. This lining provides additional wear and corrosion resistance, extending the lifespan of the barrel. Non-lined barrels are made from a single material and are less expensive than lined barrels. However, they may not be suitable for applications that involve highly abrasive or corrosive materials.

When choosing a barrel design, consider the specific requirements of your production process, such as the type of material, the desired output rate, and the level of temperature control required. You may also need to consider the compatibility of the barrel design with the rest of your extrusion equipment.

4. Size and Capacity

The size and capacity of the twin screw barrel are important factors to consider when choosing the right one for your application. The size of the barrel is typically determined by the diameter and length of the screws. The diameter of the screws affects the throughput capacity of the extruder, while the length of the screws affects the mixing and melting efficiency.

When choosing the size of the twin screw barrel, consider the specific requirements of your production process, such as the desired output rate, the type of material, and the level of mixing required. You may also need to consider the available space in your production facility and the compatibility of the barrel size with the rest of your extrusion equipment.

5. Quality and Reliability

Finally, it's important to choose a twin screw barrel that is of high quality and reliability. A high-quality barrel will offer better performance, longer lifespan, and fewer maintenance issues. When evaluating the quality of a twin screw barrel, consider factors such as the material quality, the manufacturing process, and the reputation of the manufacturer.

Look for a manufacturer that has a proven track record of producing high-quality twin screw barrels. Check for certifications and accreditations, such as ISO 9001, which indicate that the manufacturer follows strict quality control standards. You may also want to read customer reviews and testimonials to get an idea of the manufacturer's reputation and the quality of their products.

In conclusion, choosing the right twin screw barrel is a critical decision that can significantly impact the efficiency, quality, and profitability of your production. By considering factors such as material compatibility, screw configuration, barrel design, size and capacity, and quality and reliability, you can select the perfect twin screw barrel for your specific needs.

If you're in the market for a twin screw barrel, I encourage you to explore our range of Double Screw Extruder Barrel, Screw Element Conveying Part, and Parallel Barrel Screw. Our products are designed and manufactured to the highest standards of quality and performance, and we offer a wide range of options to meet the specific needs of our customers.

If you have any questions or need further assistance in choosing the right twin screw barrel for your application, please don't hesitate to contact us. Our team of experts is always ready to help you find the perfect solution for your extrusion needs.

References

- "Twin Screw Extrusion: Technology and Principles" by James L. White and K. P. Bhattacharyya

- "Extrusion of Polymers: Theory and Practice" by M. Xanthos

- "Handbook of Plastic Extrusion Technology" by Edward A. Gradoski and John L. Schrenk