Hey there! As a supplier of Parallel Barrel Screws, I often get asked whether these screws can be used in the pharmaceutical industries. Well, let's dive right into this topic and find out.

First off, let's understand what a parallel barrel screw is. A parallel barrel screw is a key component in extrusion processes. It's designed to convey, compress, and melt materials within an extruder. In simple terms, it's like the engine of an extruder, making sure everything runs smoothly.

Now, the pharmaceutical industry has some pretty strict requirements. Quality, precision, and safety are of the utmost importance. So, can a parallel barrel screw meet these high - standards? The answer is a resounding yes!

One of the main advantages of using a parallel barrel screw in the pharmaceutical industry is its ability to provide consistent mixing. In pharmaceutical manufacturing, it's crucial to have a uniform blend of active pharmaceutical ingredients (APIs) and excipients. The parallel barrel screw can achieve this by creating a homogeneous mixture through its unique design. It has different flight configurations and mixing elements that can break down agglomerates and disperse the components evenly.

Another great thing about parallel barrel screws is their flexibility. They can be customized to suit different pharmaceutical applications. For example, if you're dealing with heat - sensitive APIs, you can design the screw with special cooling mechanisms to prevent degradation. Or, if you need to handle high - viscosity materials, you can choose a screw with a specific flight pitch and depth to ensure proper conveyance.

Let's talk about hygiene. The pharmaceutical industry has strict regulations regarding cleanliness and sterility. Parallel barrel screws can be made from high - quality materials such as stainless steel, which is resistant to corrosion and easy to clean. This helps in maintaining a hygienic production environment and preventing cross - contamination between different batches.

Now, I want to mention some of our products that are relevant to the pharmaceutical industry. We offer Screw Barrel Element for Masterbatch. These elements can be used to enhance the mixing performance of the parallel barrel screw. They are designed to provide intense shearing and distributive mixing, which is essential for getting a high - quality pharmaceutical product.

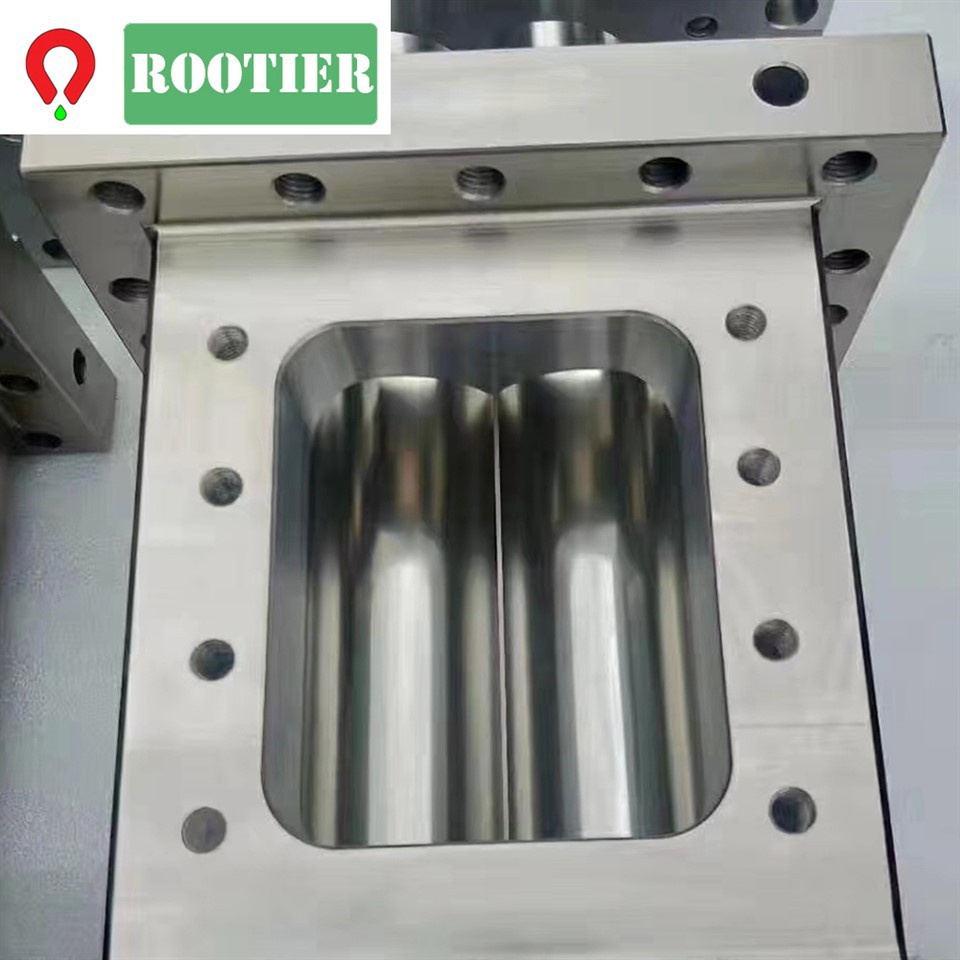

Our Double Screw Extruder Barrel is also a great option. It works in tandem with the parallel barrel screw to ensure efficient extrusion. The double - screw design allows for better control over the process parameters such as temperature, pressure, and residence time. This is crucial for pharmaceutical manufacturing, where even a small deviation in these parameters can affect the quality of the final product.

And of course, our Twin Screw Extruder Barrel is a top - notch choice. It provides excellent self - wiping action, which helps in reducing the risk of material buildup and ensures consistent product quality.

However, there are also some challenges when using parallel barrel screws in the pharmaceutical industry. One of the main challenges is the cost. Custom - designed parallel barrel screws can be quite expensive, especially when you factor in the high - quality materials and precision manufacturing required. But in the long run, the benefits of using these screws often outweigh the initial cost.

Another challenge is the need for proper maintenance. Since the pharmaceutical industry has such high standards, regular maintenance of the parallel barrel screw is essential. This includes cleaning, inspection, and replacement of worn - out parts. But don't worry, we provide comprehensive after - sales support to help our customers with these tasks.

In conclusion, parallel barrel screws can definitely be used in the pharmaceutical industries. They offer many advantages such as consistent mixing, flexibility, and hygiene. Our products, like the Screw Barrel Element for Masterbatch, Double Screw Extruder Barrel, and Twin Screw Extruder Barrel, are designed to meet the specific needs of the pharmaceutical industry.

If you're in the pharmaceutical industry and are looking for high - quality parallel barrel screws, we'd love to have a chat with you. Whether you have questions about our products, need a custom - made solution, or want to discuss your specific requirements, we're here to help. Just reach out to us, and let's start a conversation about how our parallel barrel screws can improve your pharmaceutical manufacturing process.

References

- "Extrusion Technology for Pharmaceuticals" by Ian G. Tucker

- "Handbook of Pharmaceutical Excipients"