Hey there! As a supplier of Twin Screw Barrels, I often get asked about the degassing performance of these nifty pieces of equipment. So, let's dive right in and break it down.

First off, what exactly is degassing in the context of twin screw barrels? Well, when you're processing polymers, there are often volatile substances like moisture, monomers, and other low - molecular - weight compounds trapped inside the material. Degassing is the process of removing these unwanted volatiles from the polymer melt. This is super important because if these volatiles aren't removed, they can cause all sorts of problems in the final product, like poor surface finish, reduced mechanical properties, and even bubble formation.

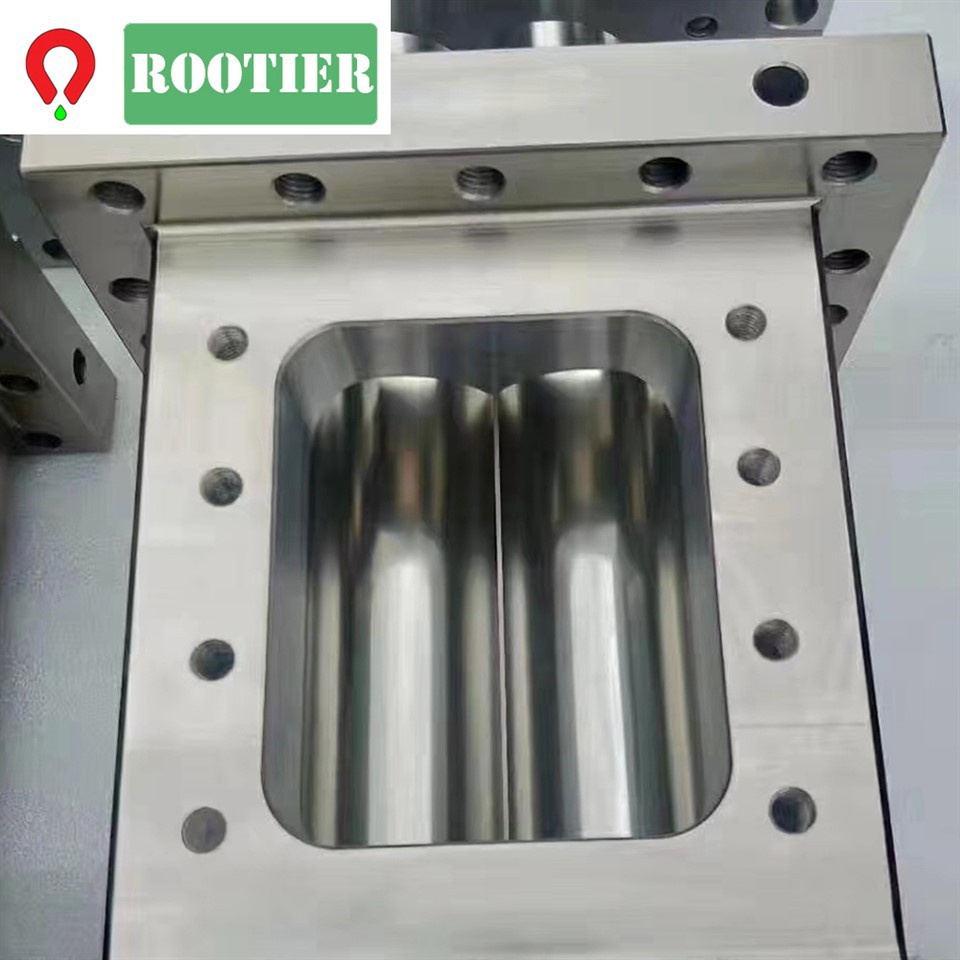

Now, let's talk about how twin screw barrels achieve degassing. Twin screw barrels are designed with a unique configuration that allows for efficient mixing and transport of the polymer melt. The screws rotate inside the barrel, creating a series of compression and decompression zones. When the polymer melt enters a decompression zone, the pressure drops suddenly. This drop in pressure causes the volatile substances to vaporize, turning from a liquid or solid state into a gas.

The design of the twin screw barrels plays a crucial role in the degassing process. For example, the screw elements can be customized to create different mixing and shearing patterns. Some screw elements are designed to break up the polymer melt into smaller droplets, increasing the surface area available for the volatiles to escape. This is known as the "shear - induced" degassing mechanism.

Another important factor is the venting system. Twin screw barrels are typically equipped with one or more vents along the length of the barrel. These vents are connected to a vacuum system that sucks out the vaporized volatiles. The location and size of the vents are carefully chosen to optimize the degassing efficiency. If the vents are placed too close to the feed section, the polymer melt may not have had enough time to reach the right temperature and viscosity for effective degassing. On the other hand, if the vents are too far downstream, the volatiles may have already been re - absorbed by the polymer melt.

The temperature of the polymer melt also affects the degassing performance. Higher temperatures generally increase the vapor pressure of the volatiles, making it easier for them to escape. However, too high a temperature can also cause thermal degradation of the polymer, which is not desirable. So, it's a delicate balance that needs to be maintained.

The type of polymer being processed also matters. Different polymers have different vapor pressures and solubility characteristics for the volatiles. For example, some polymers have a high affinity for moisture, which means they can hold onto water molecules tightly. In these cases, more aggressive degassing techniques may be required, such as using a higher vacuum level or longer residence time in the barrel.

Now, let's take a look at some real - world applications of twin screw barrels and their degassing performance. One common application is in the production of masterbatches. Masterbatches are concentrated mixtures of pigments, additives, or other functional materials in a polymer carrier. During the production of masterbatches, it's essential to remove any moisture or other volatiles to ensure consistent color and performance. You can check out more about the Screw Barrel Element for Masterbatch on our website.

Another application is in the processing of engineering plastics. Engineering plastics are used in a wide range of high - performance applications, such as automotive parts, electronic components, and aerospace components. These plastics often require high - quality degassing to meet the strict performance requirements. Conical screw barrels, like our Conical Screw Barrel and Conical Barrel, are sometimes used in these applications because they can provide a more uniform pressure distribution and better mixing, which can improve the degassing performance.

So, how can you measure the degassing performance of twin screw barrels? There are several methods available. One common method is to measure the residual volatile content in the final product. This can be done using techniques such as gas chromatography or thermogravimetric analysis. Another method is to measure the vacuum level in the venting system. A higher vacuum level generally indicates better degassing efficiency, but it's important to note that other factors, such as the flow rate of the polymer melt and the size of the vents, can also affect the vacuum level.

In conclusion, the degassing performance of twin screw barrels is a complex process that depends on many factors, including the design of the barrels, the screw elements, the venting system, the temperature of the polymer melt, and the type of polymer being processed. As a supplier of Twin Screw Barrels, we have the expertise and experience to help you optimize the degassing performance for your specific application. Whether you're producing masterbatches, engineering plastics, or any other polymer - based product, we can provide you with the right twin screw barrel solution.

If you're interested in learning more about our Twin Screw Barrels or discussing your degassing requirements, feel free to reach out to us. We're always happy to have a chat and see how we can help you achieve the best possible results in your polymer processing operations.

References:

- "Polymer Processing: Principles and Design" by M. Xanthos

- "Twin - Screw Extrusion: Technology and Principles" by J. L. White and K. P. Potente