Hey there! As a conical barrel supplier, I've seen firsthand how important it is to stack these barrels safely. Whether you're a small business owner or a large industrial operator, improper stacking can lead to all sorts of problems, from barrel damage to serious safety hazards. In this blog post, I'm gonna share some tips on how to stack conical barrels safely.

Understanding Conical Barrels

First off, let's talk a bit about conical barrels. These barrels are unique because of their shape - they're wider at the top and narrower at the bottom. This shape gives them some advantages, like being more stable when standing upright, but it also presents some challenges when it comes to stacking.

Conical barrels are commonly used in various industries for storing and transporting liquids, chemicals, and other materials. They come in different sizes and materials, such as plastic and metal, each with its own set of characteristics.

Pre - stacking Checks

Before you start stacking those conical barrels, you need to do some checks. First, inspect the barrels for any damage. Look for cracks, dents, or leaks. A damaged barrel can compromise the stability of the entire stack and is a major safety risk. If you find a damaged barrel, don't stack it. Instead, either repair it if possible or dispose of it properly.

Next, make sure the barrels are clean. Any residue inside or outside the barrel can make it slippery, increasing the chances of the stack toppling over. Wipe down the barrels and remove any debris.

Choosing the Right Location

The location where you stack your conical barrels is crucial. You want a flat and level surface. Uneven ground can cause the barrels to shift and fall. If the surface is not naturally flat, you might need to use a pallet or a platform to create a level base.

Also, consider the environment. Avoid areas with high traffic, as accidental bumps can knock over the stack. And make sure the location is well - ventilated, especially if the barrels contain volatile or hazardous materials.

Stacking Techniques

Now, let's get into the actual stacking. There are a few different ways to stack conical barrels, but the key is to ensure maximum stability.

Single - layer Stacking

For smaller operations or when you don't have a lot of barrels, single - layer stacking is a good option. Place the barrels side by side with their bases firmly on the ground. Make sure there's enough space between each barrel so that you can easily access them when needed. This method is simple and safe, but it does take up a lot of floor space.

Multi - layer Stacking

If you need to save space, multi - layer stacking is the way to go. But you have to be extra careful. Start by placing a row of barrels on the base layer. Then, for the second layer, place the barrels in the gaps between the barrels on the first layer. This interlocking pattern helps to distribute the weight evenly and increases stability.

However, you can't stack too many layers. The number of layers depends on the size, material, and the weight of the contents of the barrels. As a general rule, for plastic conical barrels, don't stack more than 3 - 4 layers. Metal barrels can usually handle a few more layers, but you still need to be cautious.

When stacking, always keep the center of gravity of the stack as low as possible. This means starting with the larger end of the barrels at the bottom. If you stack them the other way around, the stack will be top - heavy and more likely to fall.

Using Safety Equipment

To further enhance safety, you can use some safety equipment. Straps or bands can be used to secure the barrels together. Wrap the straps around the barrels at different levels to hold them in place. This is especially useful for multi - layer stacks.

You can also use corner protectors. These are small pieces of material that you place at the corners of the stack. They help to prevent the barrels from rubbing against each other and getting damaged, and they also add a bit of extra stability.

Additional Considerations

If you're dealing with barrels of different sizes, try to stack them in a way that makes sense. Larger barrels should be at the bottom, and smaller ones on top. This not only helps with stability but also makes it easier to access the barrels later.

Also, if the barrels contain different materials, make sure to separate them properly. Some materials might react with each other if they come into contact, so it's important to keep them apart.

Related Products

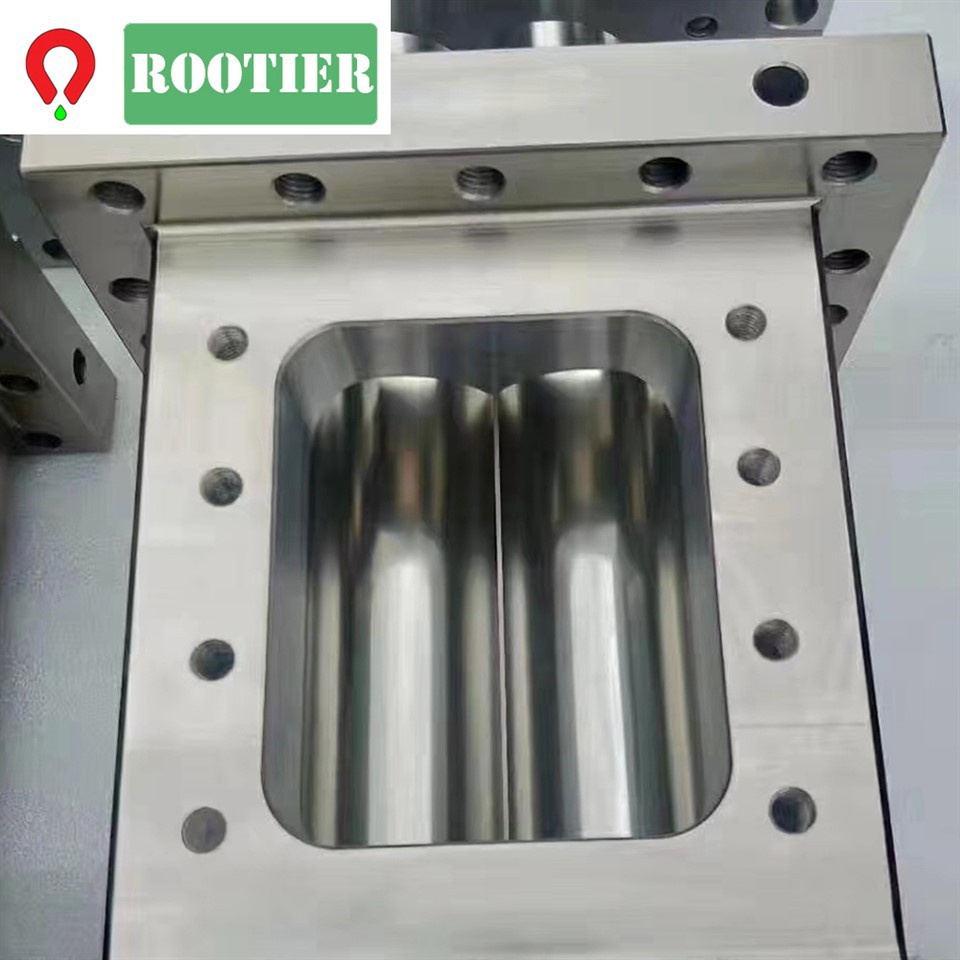

As a conical barrel supplier, we also offer some related products that might be useful for your operations. For example, if you're involved in extrusion processes, you might be interested in our Parallel Extruder Cylinder Screw. It's designed to work efficiently with various types of barrels.

We also have the Screw Barrel Element for Masterbatch. This product is great for those who need to handle masterbatch materials in their production.

And if you're looking for a parallel twin - screw solution, check out our Parallel Twin Screw Barrel. It provides high - quality performance and reliability.

Conclusion

Stacking conical barrels safely is not rocket science, but it does require attention to detail. By following these tips, you can reduce the risk of accidents and ensure the long - term safety of your workplace. Remember, safety should always be your top priority.

If you're interested in purchasing conical barrels or any of our related products, feel free to reach out for a procurement discussion. We're here to help you find the best solutions for your needs.

References

- Industrial Safety Handbook, 3rd Edition

- Best Practices for Storage and Handling of Barrels, Industry Standards Guide